Three Bond 2273D

Adhesive Bonding Technology

Three Bond 2273D is a one-component epoxy resin with enormously high shear, impact and impact resistance. It has been specially developed for induction hardening with HF loops within seconds and is easy to automate or manually process with standard dosing systems.

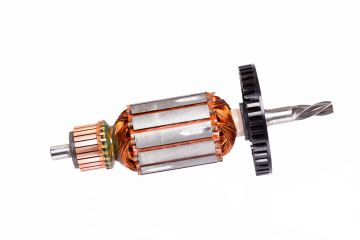

Despite the moderate glass transition temperature of 115 ° C, it is particularly well suited for use at higher temperatures due to its excellent adhesion to a variety of different materials. This makes Three Bond 2273D the ideal choice when it comes to fast and secure bonding and affixing of magnetisable materials such as ferrites and steel sheets, for example in electric motors, and the stress of elevated temperatures in the final applications.

Contact Form

Features

The search results from SUBSTRATEC are not sales recommendations and/or professional technical advice. It is only intended to make it easier for the user to pre-select suitable system that may be available. SUBSTRATEC gives no guarantee that the system suggested is successful or suitable for the specific area of application of the user. In the event of any questions regarding the use and suitability for the specific application, the user has the possibility to directly contact the respective technical contact person of the relevant manufacturer or supplier. See for further information Terms of Use.