PowerWeld 2part MMA

Adhesive Bonding Technology

Structural Bonding in modern Manufacturing and Processing demands extremely high degrees of strength, speed and safety for the functional bonding of modern materials.

The modified Methyl Methacrylat Ester (MMA) is a 2 component structural adhesive for metal bonding, modern difficult to bond plastics and innovative composites. You can achieve high strength, tough yet slightly elastic bonds, mostly without chemical or mechanical preparation of the surface.

In comparison to classic structural bonding (e.g. with Epoxies), MMA scores with its exceptional tear strength, remaining elasticity as well as its high degree of resistance to temperature extremes. The Power Weld adhesive is easy to use and mostly non runny, because of its thixotropic viscosity.

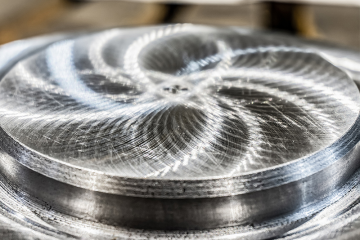

MMA is a state of the art modern alternative to many conventional bonding methods like welding, soldering or riveting.

**Advantages.""

- High lapshear resistance

- Very good chemical resistance

- High temperature specification

- Non runny

- Partly no primer/ No sanding

- Remains elastic

- Wide adhesion spectrum

- Fills cuts and gaps up to 4mm

- Good Reworkability

- UV stable

Consistent Performance for industrial needs. Exploration of the fast growing automotive aftermarket in the early nineties opened new opportunities in this particular industry.

Contact Form

Features

The search results from SUBSTRATEC are not sales recommendations and/or professional technical advice. It is only intended to make it easier for the user to pre-select suitable system that may be available. SUBSTRATEC gives no guarantee that the system suggested is successful or suitable for the specific area of application of the user. In the event of any questions regarding the use and suitability for the specific application, the user has the possibility to directly contact the respective technical contact person of the relevant manufacturer or supplier. See for further information Terms of Use.