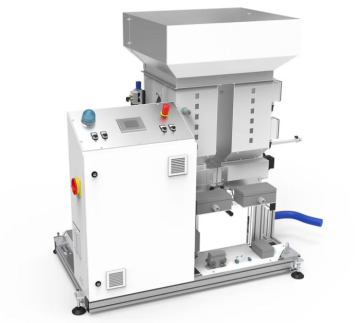

H&H Premelter

Dosing and Processing Technology

Melting machines for hotmelts and reactive PUR adhesives.

Our standard premelters for adhesive application and coating systems can melt up to 240 kg of adhesives per hour. Optionally, we can also implement higher melting capacities for specific customers.

Our Melters automatically supply the machine with hot, liquid adhesive – but only ever as much as is needed at the specific point in time.

We manufacture premelters for:

- Granulated hotmelts

- Reactive adhesives (PUR, polyurethane-based) in a closed-loop system

Control is carried out by means of capacitive level control in the melting tank of the respective application machine or using a timer.

Thanks to their individual and needs-based control, our premelting systems are extremely energy-saving and economical. Our premelting systems can be expanded even further with a wide range of accessories such as a vacuum conveyor with a granulate reservoir, for instance.

Efficient premelters from H&H Klebetechnologie: development, production, installation, service – all from a single source.

Bespoke adhesive application systems. As an ÖKOPROFIT-certified company, H&H Klebetechnologie designs and manufactures innovative adhesive application machines and accessories.

Contact Form

Features

The search results from SUBSTRATEC are not sales recommendations and/or professional technical advice. It is only intended to make it easier for the user to pre-select suitable system that may be available. SUBSTRATEC gives no guarantee that the system suggested is successful or suitable for the specific area of application of the user. In the event of any questions regarding the use and suitability for the specific application, the user has the possibility to directly contact the respective technical contact person of the relevant manufacturer or supplier. See for further information Terms of Use.