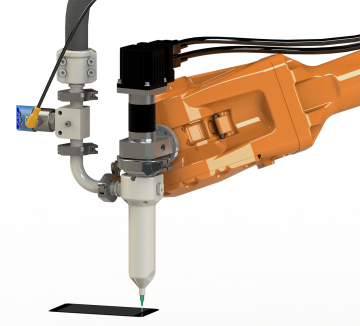

ViscoTec Metal-free dispenser

Dosing and Processing Technology

Chemical reactions such as hardening or crystallization are avoided by avoiding metal in the area of the dispenser in contact with the material.

Characteristics:

- Special polymer pump and sealing housing

- 100 % metal-free rotor shaft

- Special rotor / stator geometry

- Wide range of stator materials

- Luer-adapter for dispense tips

Suitable for:

- Anaerobic curing adhesives

- Sulphuric acids

- Acetic acid

- Bases

- Sulphur and chloride based electrolytes

- Sodium hypochloride (bleaching lye)

- Hydrogen peroxide

- lonic liquids

- and others

ViscoTec is a manufacturer of systems for conveying, dosing, application, filling and removal of low to high viscosity adhesives.

Contact Form

Features

The search results from SUBSTRATEC are not sales recommendations and/or professional technical advice. It is only intended to make it easier for the user to pre-select suitable system that may be available. SUBSTRATEC gives no guarantee that the system suggested is successful or suitable for the specific area of application of the user. In the event of any questions regarding the use and suitability for the specific application, the user has the possibility to directly contact the respective technical contact person of the relevant manufacturer or supplier. See for further information Terms of Use.