Bonding XPS rigid foam to NBR

These days bonding processes are becoming ever more complex and the projects ever more challenging. Substratec Ltd supports your business in finding suitable adhesive bonding methods, corresponding surface technologies and relevant application systems, both on- and offline:

Search engine for adhesives technologies >>>

Features

Extruded polystyrene (rigid foam)

Acrylonitrile-butadiene rubber or nitrile rubber is a material of the monomers acrylonitrile and 1,3-butadiene which belongs to the group of synthetic rubbers. Nitrile rubber vulcanization products are highly resistant to oils, fuel and aliphatic hydrocarbons. The proportion of acrylonitrile can vary greatly and thus affect properties such as cold flexibility or swelling resistance. It is often used in disposable lab or cleaning gloves. © 2021 SUBSTRATEC. All Rights Reserved.

Preview results

Bonds immediately, is the new generation of the mounting adhesive, is not shrinking, is very well suited for natural stones, hardens quickly.

Low odor, permanently elastic, wet on wet applicable, good resistance to oils, fats, water, aliphatic solvents etc.

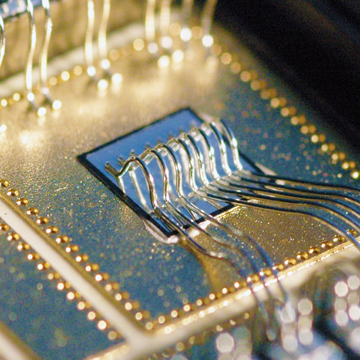

1-part room-temperature curing, highly flexible polyurethane-adhesive with excellent electrical conductivity. It is used in micro electronics, hybrid and electronic applications.

Excellent adhesive properties on many materials, low blooming, thixotropic, drip free, remains flexible, mechanical editable.