dynamicLine - Dynamic Mixing

Dosing and Processing Technology

Gasketing, bonding, potting.

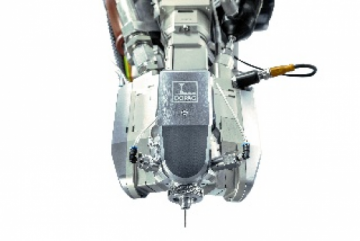

With the dynamicLine, DOPAG offers an efficient and economical solution for gasketing/FIPFG applications in various industries.

DynamicLine was developed for the precise processing of highly reactive gasketing, adhesives and pottingcompounds based on polyurethane and silicone – especially when rapid mixing and application are required. Depending on the application, one of the two processes below is used in gasketing.

FIPFG: formed-in-place foam gaskets When gasketing with FIPFG technology, reactive polymer materials are metered precisely, mixed andthen automatically applied on a component along a contour or a level surface. After a certain reaction timedependent on the material and other factors (temperature, humidity), the material foams up and bonds firmlyto the component. Foam gasketing has many advantages compared to cut or manually applied gasketing.The start and end point of the gasket are connected practically seamlessly. They bond without any additionaladhesive tape and there is considerably less waste.

FIPG: formed-in-place gaskets DynamicLine is also perfect for FIPG (formed-in-place gaskets). Here, non-foaming, highly reactive sealingsystems that cannot be processed using a static mixing system are metered, mixed and applied.

Your Partner for Metering and Mixing Technology. Solutions for gasketing, potting and bonding applications.

Contact Form

Features

The search results from SUBSTRATEC are not sales recommendations and/or professional technical advice. It is only intended to make it easier for the user to pre-select suitable system that may be available. SUBSTRATEC gives no guarantee that the system suggested is successful or suitable for the specific area of application of the user. In the event of any questions regarding the use and suitability for the specific application, the user has the possibility to directly contact the respective technical contact person of the relevant manufacturer or supplier. See for further information Terms of Use.