Fe-Ma-Tech Spray Valves

Dosing and Processing Technology

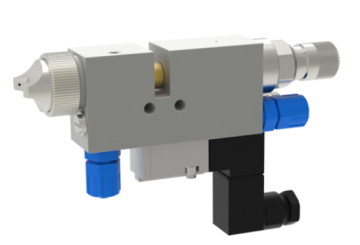

FE-MA-TECH® spray valves of series MKDD - S are specially designed for the application of glues and adhesives.

Also other fluids as oils and release agents can be sprayed. They can be used for continuous or intermitted employments. Via the direct mounted 3/2 way solenoid valve the control air is operated. Short air channels within the MKDD valve body give it very fast and exact needle intermission cycles. The atomizing air is operated by an external valve. The fastening of this valve to a machine can be done via the two bores (thread M5). Optional clamps are available. Different versions of air caps allow an optimal spray jet for each application.

- available nozzle dimensions: ø 0.2 / 0.3 / 0.5 / 0.8 / 1.0 / 1.2 / 1.5 / 2.0 / 2.5 mm

- ratchet regulator for easy adjusting amount of fluid

- solenoid valves in different tensions (24V/DC / 110V/AC / 220V/AC)

- different nozzles and air caps for individual application requirements

FE-MA-TECH® works very successfully throughout Europe in the fields of mechanical engineering, machine service and gluing system service for leading companies in furniture production, wood processing, as well as in the food and packaging industry.

Contact Form

Features

The search results from SUBSTRATEC are not sales recommendations and/or professional technical advice. It is only intended to make it easier for the user to pre-select suitable system that may be available. SUBSTRATEC gives no guarantee that the system suggested is successful or suitable for the specific area of application of the user. In the event of any questions regarding the use and suitability for the specific application, the user has the possibility to directly contact the respective technical contact person of the relevant manufacturer or supplier. See for further information Terms of Use.