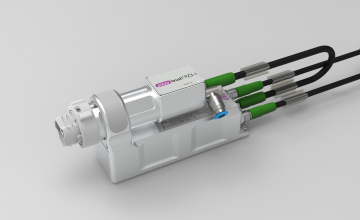

piezobrush®PZ3-i

Surface Treatment

The piezobrush® PZ3-i is the future industry standard for cold plasma applications. A compact design, low power consumption and simple, tool-free maintenance enable cost-effective integration into new and existing production lines.

With the piezobrush® PZ3-i, further pre-treatments such as the application of environmentally harmful chemical primers or flame retardation are no longer necessary. In addition, even large, poorly integrated high-performance plasma systems can be easily replaced.

The integration unit consists of a driver housing and a module carrier. A selection of different modules allows the perfect adaptation to almost any application. The unit itself has a modular design, so that the treatment width can be easily increased by stringing together several piezobrush® PZ3-i units. In this way, optimal adhesion results can be achieved with little effort.

Communication is possible via digital I/O or the integrated CANopen bus interface. The use of CANopen allows a significantly expanded scope of control and process control and significantly reduces the amount of connection cables required for modular solutions with several piezobrush® PZ3-i individual devices.

relyon plasma offers a wide range of specialized plasma components for manual applications and inline processes. Atmospheric pressure plasmas have a remarkable combination of properties that allow unique surface treatment.

Contact Form

Features

The search results from SUBSTRATEC are not sales recommendations and/or professional technical advice. It is only intended to make it easier for the user to pre-select suitable system that may be available. SUBSTRATEC gives no guarantee that the system suggested is successful or suitable for the specific area of application of the user. In the event of any questions regarding the use and suitability for the specific application, the user has the possibility to directly contact the respective technical contact person of the relevant manufacturer or supplier. See for further information Terms of Use.