Development & Consulting surface technology

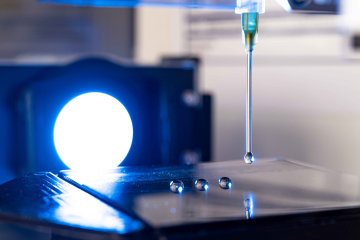

Surface Treatment

Often, product quality depends on one decisive variable - the quality of the surface. Achieving this through the right settings in the processing procedure is often a challenge.

However, speckling, streaks, scratches or even an incorrect design of the surface can already be avoided in the development phase. In plastics processing, there are also numerous other examples of interface phenomena. These include surface treatments to increase wetting of paints, coatings and adhesives, adhesion forces during bonding and painting, demolding behavior during injection molding, melt residues during hot plate welding, and friction and wear properties of plastics. All these phenomena can be described by characterizing the mechanical surface structure, the chemical-physical surface properties, material composition and adhesion forces, and can thus also be specifically influenced by changing these parameters.

In addition to the research and service activities in the described focal areas, the transfer of results is rounded off by specialist conferences, courses and training courses.

Due to our extensive equipment as well as our broad know-how we are glad to help you. Find out more about our activities in this area here.

SKZ - Plastics Technology Centre. Safe to rely! We are enabler for our customers.

Contact Form

Features

The search results from SUBSTRATEC are not sales recommendations and/or professional technical advice. It is only intended to make it easier for the user to pre-select suitable system that may be available. SUBSTRATEC gives no guarantee that the system suggested is successful or suitable for the specific area of application of the user. In the event of any questions regarding the use and suitability for the specific application, the user has the possibility to directly contact the respective technical contact person of the relevant manufacturer or supplier. See for further information Terms of Use.