SM Klebetechnik Vertriebs GmbH

Adhesive Bonding Technology

We construct the suitable system for each type of adhesive and for each form of application. As one of the leading international manufacturers of hotmelt and application facilities, we offer you series-produced devices and individual specialised machines for efficient adhesive processing.

We plan your complex hotmelt coating facilities from A to Z, including a comprehensive test phase in our technical centre, as well as guaranteed short delivery times and our reliable global assembly and maintenance service.

SM Klebetechnik is involved in all branches of industry that use hot glue, hotmelt, adhesive and sealing substances.

Otto-Hahn-Str. 19a

D-52525 Heinsberg

Germany

Features

Products

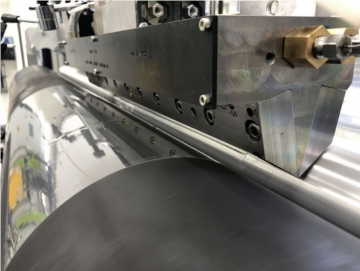

Heated contact-less slot-die application head assembly to apply accurately 2 different thermoplastic hotmelt-adhesives at same time for special multi-layer composites production in continuous coating operation.

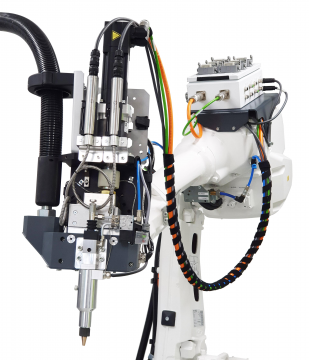

Heated and volumetrically controlled QX8500 - sealant application system for precise and synchronized material bead placement in intermittend or continous gun-operation and in corellation with a robot automation unit.

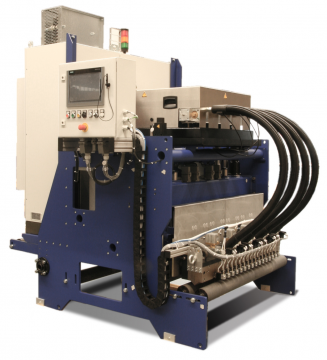

Heated bitumen coating-system for cost-efficient production of bituminous roof membranes in standard- and self-adhesive versions based on various web carrier materials, equipped with melting- and dosing units and flexible slot-die technologies.

Heated hot-melt spray system for the cost-optimized bonding of sheet material and molded parts, equipped with a premelting and metering buffer-unit as well as flexible and adjustable spray nozzle technology.

Heated drum melter with automated air relief and seamless plate-seal to process hotmelt-adhesives and sealants from smooth wall 200 kg / 55 Gal. drums with volumetric metering pump rates.

Melting system for gentle melting and processing of moisture-curing hotmelt adhesives in 18kg candle shape wraped in foil-bags, with buffer-reservoir for interruption-free processing and volumetric operating gearpump.

Drum emptying system with heated, seal-less immersion plate for distributing low viscose thermoplastics and liquides from 200 Liter drum-containers.